CNC Router Bit Types (Speeds & Feeds) and Buying Guide

If you’re just starting out with CNC routers or looking to deepen your knowledge of this essential tool, you’ve come to the right place. Understanding the nuances of CNC router bits is important not only for making the right purchasing decisions but also for optimizing your CNC router’s performance. This article provides a beginner’s guide to CNC router bits, explaining the key information you need to know when starting out. It covers the essential types of router bits, what to look for when buying, and recommendations for starter bit sets. You will learn what are the best router bit sets for beginners!

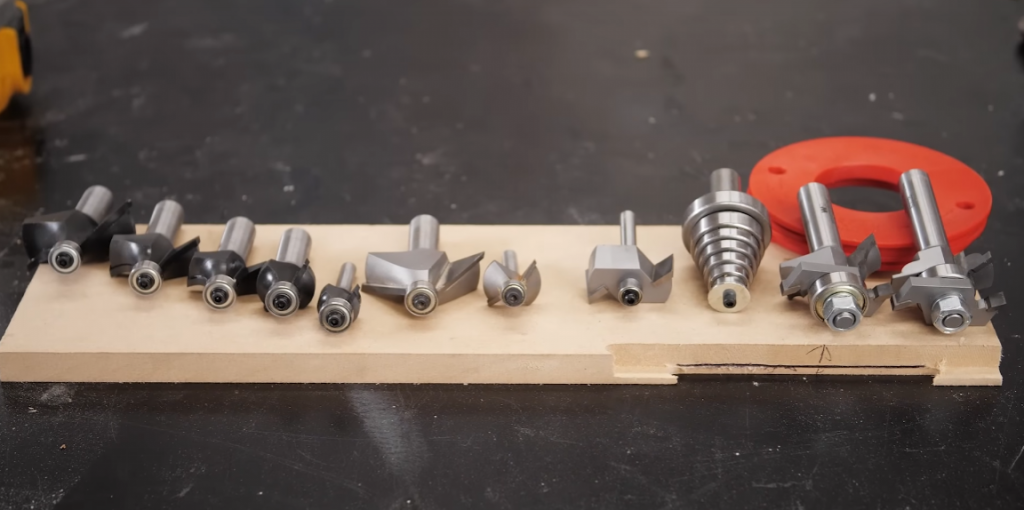

Types of CNC Router Bits

There are eight primary families of CNC router bits, each designed for specific tasks:

- Endmills

Endmills are side cutting tools with a flat bottom, meant for cutting square slots or profiling with square corners. They come in varying diameters like 1/4″, 1/2″, etc. - V-Bits

V-bits have an angled point, commonly used for lettering, detailed designs, and adding style/flair. Common angles are 90°, 60°, 45°, and 30°. - Ball Nose Bits

Ball nose bits are similar to endmills but with a radiused spherical tip, leaving rounded edges on parts instead of sharp corners. - Surfacing/Facing Bits

Large diameter endmills (e.g. 3″) used for hogging out material quickly and surfacing spoilboards. - Carving/Engraving Bits

Specialized tapered bits for machining fine 3D details and reliefs. - T-Slot Cutters

For cutting T-shaped slots to hang signs flush against a wall. - Bowl Cutters

Radiused endmills used for machining bowls/dishes with rounded interiors. - Drag Bits

Including solid carbide diamond drag bits for engraving on glass/acrylic and specialized drag tools like pens and knives.

Router Bit Construction, Materials, Speeds, Feed Rates

Router bits are made from either high-speed steel (HSS) or carbide. Carbide bits are made from tungsten carbide which is harder, more wear-resistant, and can hold an edge 20-50x longer than HSS at higher temperatures. Carbide bits produce better finishes and last much longer though they are more expensive. The shank (non-cutting portion) is usually made from a different steel alloy. Quality shanks should be wear and deformation resistant.

1. Cutting Edges (Types)

- Flutes: The cutting edges of router bits, typically one or two per bit. More flutes don’t necessarily equate to faster cutting but can improve finish quality.

- Spiral Types: Includes straight, upcut, and downcut spirals. Each type affects how material chips are evacuated and influences the quality of the cut.

Up-cut spiral bits are better for preventing chip buildup on deep pocket cuts but can leave a rougher edge. Down-cut spirals leave cleaner edges but allow chips to buildup. Straight flutes produce an interrupted cut which can cause vibration.

2. Materials

- High-Speed Steel (HSS): Less expensive but dulls faster, suitable for less demanding tasks.

- Carbide: Known for its durability and sharpness, ideal for professional quality cuts.

Coating on Router Bits

Some router bits have thin coatings applied like black oxide, cobalt, tungsten nitride, or titanium nitride coatings. Coatings can help manage heat and friction but are not essential. Uncoated carbide bits perform just as well and coatings simply add cost.

Cheap Router Bits

Very cheap router bits from unknown manufacturers should be avoided, as they are typically made from low-quality materials, have poor heat treatments, and quickly become dull producing poor finishes.

3. Router Speed

Router speed refers to the rotation rate of the router bit and is usually measured in revolutions per minute (RPM). Adjustable speeds allow the router to handle different materials and bit sizes effectively:

- Smaller Bits:Can generally be run at higher speeds.

- Larger Bits:Should be run at lower speeds to prevent burning and ensure control.

General Speed Guidelines:

- Under 1 inch:Up to 24,000 RPM.

- 1 to 2 inches:Around 18,000 RPM.

- 2 to 2.5 inches:Around 16,000 RPM.

- 3 inches and above:Below 12,000 RPM.

It’s essential to consult the router’s manual for specific speed recommendations and adjust based on the material type and the desired finish.

4. Feed Rate

Feed rate is the speed at which the material is fed into the router bit or the router is moved across the material. It’s crucial for the quality of cut and the life of the router bit:

- Optimal Feed Rate:Should match the capability of the bit to remove material efficiently without overloading.

- Signs of Incorrect Feed Rate:

- Too Fast:May cause the router to jerk or the bit to screech, indicating the bit is taking too much material.

- Too Slow:Can result in burning due to excessive friction.

Adjustment Tips:

- Listen for a consistent cutting sound—any screeching or chattering may indicate the need for adjustment.

- Use a light, consistent pressure without forcing the router.

Demonstrations and Practical Applications

Through practical demonstrations, Garrett illustrates how different bits perform on materials, emphasizing the importance of choosing the right bit for the right job to achieve optimal results.

Buying Guide: What CNC Router Bits You Need

For starting out, the essential router bits needed are:

- Flat endmills in 1/4″, 1/2″, 3/4″ diameters

- V-bits in 90°, 60°, 30° angles

- Ball nose bits in 1/4″ and 1/2″ diameters

- Surfacing/facing bit around 3″ diameter

These will cover most basic 2D/2.5D jobs like profiling, pocketing, lettering, contouring, and squaring stock. Additional specialty bits like T-slot, bowl, carving, and drag bits can be added as needed for more advanced projects.

Where to Get CNC Router Bits

Purchasing a complete balanced set of quality router bits from major brands like Amana can cost $300+. Complete sets are difficult to source.

However, bundles can be purchased from trusted resellers like IDC Woodcraft that include:

- 9 essential carbide router bits (endmills, v-bits, ball nose, surfacing bit)

- Collets to fit bits in router

- Feeds/speeds guides

- Top selling font/design files

- Sample project files

Along with bits in standard diameters like 1/4″, 1/2″, 3/4″, the bundle may include specialty items like:

- 1/8″ up-cut endmill for detail work

- Large diameter surfacing/facing bit

- Up/down cut spiral endmills

This allows users to get started with a complete, high-quality router bit setup for CNC work at a reasonable cost from a trusted source.

Understanding CNC router bits in depth allows you to enhance your work’s quality and efficiency significantly. By choosing the right bits and knowing how to use them correctly, you can expand the capabilities of your CNC router far beyond basic woodworking. Whether you are a hobbyist or a professional, the right knowledge and tools are key to mastering CNC routing.