Machining High-Temperature Alloys: Characteristics, Challenges, Causes & Solutions

The machining of high-temperature alloys is crucial in various industries, including aerospace, power generation, and where high-strength, high-temperature resistant materials are essential. However, the unique properties of these alloys make them difficult to machine, in this article, we’ll explore the characteristics, challenges, and solutions for high-temperature alloy machining.

What Are High-Temperature Alloys and Common Types?

High-temperature alloy is a metal material that can work for a long time under high temperatures and certain stresses above 600 ℃. It is usually based on iron, nickel, and cobalt, and added with a large amount of strengthening elements such as chromium, aluminum, and titanium to improve its performance in hot environments.

Characteristics of High-Temperature Alloys

– Higher thermal stability: They can maintain their strength and stability at high temperatures.

– Higher strength: They have higher strength than general alloy steel.

– Lower thermal expansion coefficient: They have a lower thermal expansion coefficient, which means they are less prone to thermal deformation.

– Good fatigue resistance: High-temperature alloys are less prone to fracture when subjected to repeated stresses

Types of High-Temperature Alloys

1) Iron-based alloy: mainly composed of iron, and their properties are usually improved by adding other elements such as carbon, chromium, nickel, etc. The biggest feature of this type of alloy is its good comprehensive performance, a wide range of applications, and relatively low price. Strictly speaking, steel materials also belong to iron-based alloys, but in engineering, the two are usually distinguished. Iron-based alloys can be divided into martensitic alloy steel and austenitic heat-resistant steel, among which martensitic aging steel (18Ni type) is the most typical age-hardening iron-based alloy. In addition, iron-based high-temperature alloys have been developed from austenitic stainless steel by adding elements such as molybdenum, niobium, and titanium to enhance their durability under high-temperature conditions.

2) Nickel-based alloy: mainly composed of nickel, containing a considerable amount of elements such as chromium, molybdenum, tungsten, etc. This type of alloy has excellent high-temperature oxidation resistance, creep resistance, and corrosion resistance, and is therefore widely used in fields such as aerospace, chemical engineering, and energy. For example, the new cobalt-based high-temperature alloy is considered one of the most promising hot-end materials for aircraft engines due to its higher temperature-bearing capacity and superior high-temperature creep resistance and oxidation resistance compared to traditional nickel-based high-temperature alloys.

3) Cobalt-based alloy: primarily composed of cobalt, containing nickel, chromium, tungsten, and small amounts of molybdenum, niobium, tantalum, titanium, and other elements. This type of alloy has good high-temperature strength, high-temperature fatigue resistance, thermal shock resistance, as well as good oxidation and corrosion resistance. Cobalt-based alloys have important applications in the aviation industry, such as GH5188, a solid solution-reinforced cobalt-based high-temperature alloy commonly used in the manufacture of vortex components for aircraft engines. Cobalt-based high-temperature alloys can be used for electroplating rollers, chemical nozzles, and biomedical devices.

Challenges in High-Temperature Alloy Machining

Challenge 1: Low Thermal Conductivity

High-temperature alloys have a low thermal conductivity, typically only 20% to 40% of that of steel. This means that during machining, the cutting tool’s edge temperature can rise rapidly, leading to premature wear and tear. As a result, the cutting tool’s lifespan is significantly reduced, and the machining process becomes unstable. This is because the low thermal conductivity of high-temperature alloys prevents efficient heat dissipation, causing the cutting tool to overheat and lose its effectiveness.

Challenge 2: High Chemical Activity

High-temperature alloys have high chemical activity, which can lead to chemical reactions with the cutting tool’s coating during high-temperature machining. This reaction causes the coating to wear off quickly, rendering it ineffective in protecting the cutting tool’s body. As a result, the cutting tool’s lifespan is shortened, and the machining process becomes unstable. This is because the chemical reaction between the high-temperature alloy and the cutting tool’s coating weakens the tool’s structure and leads to premature failure.

Challenge 3: High Cutting Resistance

High-temperature alloys have a high cutting resistance, which is about 50% higher than that of medium-carbon steel. This means that the cutting tool requires higher overall strength to withstand the machining process. However, even with a stronger cutting tool, the machining process can still be unstable due to the high cutting resistance of high-temperature alloys. As a result, the cutting tool’s lifespan is reduced, and the machining process becomes more difficult to control.

Challenge 4: Surface Hardening and Residual Stress

After machining, high-temperature alloys can exhibit surface hardening and residual stress, which can lead to rapid tool wear and tear. The hardening degree can reach 200% to 500%, causing the cutting tool to wear out faster during subsequent machining operations. This is because the high-temperature alloy’s surface hardening and residual stress can cause the cutting tool to experience excessive wear and tear, leading to premature failure and reduced machining stability.

How to Machine High-Temperature Alloys Properly (Solutions to Machining Difficulties)

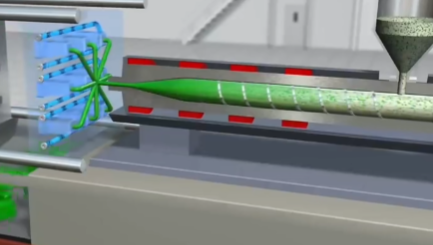

The key to machining high-temperature alloys we emphasize is controlling temperature, which is crucial for machining the most difficult-to-machine materials. Leveraging the heat dissipation capabilities of the tool’s side edge is a correct choice. Additionally, using high-temperature resistant materials or coatings for the tool is also important. Ceramic tools, with their high red hardness, are an ideal choice for machining high-temperature alloys. However, it’s essential to note that coolant should not be used, as it can cause the tool to break due to thermal expansion and contraction.

Example 1: Small to medium machining allowance

When machining high-temperature alloys under this condition, it’s best to use a solid carbide tool with a side edge and a speed of 30-50 mm/min to reduce the cutting temperature and take advantage of the tool’s heat dissipation capabilities. Additionally, a coolant should be used to completely flood the cutting area, and a tool with internal cooling or a coolant-fed tool holder is ideal. To prevent chemical reactions between the tool and the alloy, a special tool material with an inert metal coating should be used. For higher efficiency, a ceramic insert tool can be used, which can withstand higher temperatures and speeds of up to 400-600 mm/min, but its brittleness limits its use to smaller cutting widths. In high-volume machining, a specialized ceramic tool material can be used to enable faster feed rates and larger cutting widths, taking advantage of the tool’s edge angle to increase the contact area and heat dissipation. However, ceramic tools are more expensive, and if a hard alloy tool is used instead, the parameters should not be too high. It’s also important to note that if a ceramic tool is used, high-pressure air cooling should be enabled during machining, as using a coolant can cause the tool to break due to thermal expansion and contraction.

Example 2: The main spindle of the machine tool has strong torque and the roughing condition is suitable

A diamond-coated tool can be used for dynamic machining with a large cutting depth and small cutting width, taking advantage of the tool’s side edge heat dissipation capabilities to increase tool life. This approach is similar to using a solid carbide tool, where the tool’s heat dissipation capabilities are leveraged to extend its lifespan.

Example 3: Precision machining

A hyperbolic tool can be used as an alternative to a ball-nose end mill, taking advantage of the tool’s large curved radius to achieve similar effects to side-edge machining, thereby effectively increasing tool life and efficiency.

Example 4: Deep cavities

It’s best to equip the machine tool with a high-pressure coolant system, which can be paired with an internally cooled tool to reduce the temperature of the workpiece and tool, preventing deformation and wear caused by high temperatures. The coolant can also quickly remove chips, preventing their accumulation and reducing the risk of tool breakage. Additionally, a pecking machining method can be used during roughing to minimize the cutting force, and during the tool’s rotation, the rapid entry and exit of the cutting edge reduce the contact area and heat generation, not only extending tool life but also minimizing workpiece deformation to the greatest extent possible.