How To Transform A Tungsten Steel Rod Into A Milling Cutter?

From tungsten ore smelting to sintering, to cutting and coating, every step requires high technological content. This article introduces the process and technical points of each link, including powder metallurgy, sintering, cutting, and coating. Through these processes, a tungsten steel rod was successfully transformed into a stainless steel milling cutter.

The production process of Wugang milling cutters

Tungsten ore powder selection: The tungsten ore coarse powder is subjected to a series of powder selection processes, including coarse crushing, fine crushing, screening, etc., to form tungsten ore fine powder with finer particle size and higher tungsten content.

Mixed sintering: tungsten powder is automatically mixed with alloying elements such as iron and carbon that need to be added during the synthesis of tungsten alloy according to a predetermined composition ratio, and then sent to an electric arc furnace for vacuum filling. At high temperature, it is melted, mixed and sintered to form tungsten alloy blocks.

Blade forging: Using a large hammer to repeatedly forge and deform the billet, appropriately increasing or decreasing the local thickness of the material, gradually forming the coarse shape of the raw milling cutter. Intermittent cooling is required during forging to facilitate its compliance with deformation.

Polishing: Using grinding wheels with varying particle sizes for sequential polishing, known as rough grinding, fine grinding, and mirror grinding. The polishing material is diamond-like or pyroxene. During rough grinding, the main focus is on removing forging marks, while during fine grinding, the marks after rough grinding are removed and the blade is sharpened. Mirror grinding can achieve a mirror like luster.

Heat treatment: two tempering hardening+one tempering annealing. Tempering hardening can make tungsten alloys harder and finer by heating to about 800-1000 ° C and then rapidly cooling; Annealing is achieved through slow cooling to soften the quality and improve toughness.

Testing: The structure is observed under a microscope, hardness is measured using a hardness tester, and wear resistance is tested using a centrifugal resistance tester to ensure qualified quality.

Application of Wugang milling cutter

The application of Wugang milling cutters is far beyond its original milling function. As a highly disruptive and potential superhard material, the application of Wugang milling cutters in other fields has always been highly anticipated.

Recently, researchers have successfully machined an experimental high-speed aircraft using a Wugang milling cutter. This fighter jet was originally constructed using heavy metal alloys as the main body, but now it has been replaced with a black steel milling cutter, which greatly improves its hardness and toughness. After a high-speed flight test of tens of thousands of meters, the fighter jet demonstrated exceptionally excellent maneuverability and durability, inspiring the aviation industry.

At the same time, a certain aerospace development company plans to use Wugang milling cutters to retrofit their upcoming artificial satellite. The original design of the satellite housing cost up to 10 billion US dollars, but now it can be replaced by a stainless steel milling cutter, which will greatly reduce the cost. It can be seen that Wugang milling cutters are not only limited to traditional cutting techniques, but can also be applied in the field of space flight, bringing astonishing impact to various industries.

The above achievements fully prove that the revolutionary performance of Wugang milling cutters will promote the formation of new industrial formats. Perhaps its future application in more cutting-edge fields will also be highly anticipated.

Machining process of producing Wugang milling cutters in the tool factory

Testing the parameters of Wugang steel bars: X-ray emission spectroscopy is used to detect the composition, mechanical properties, and microstructure of the bars.

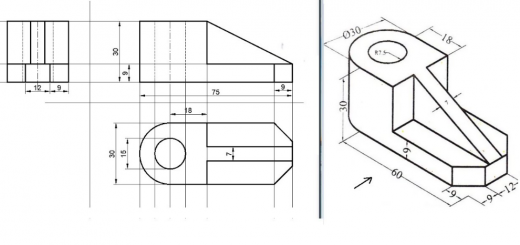

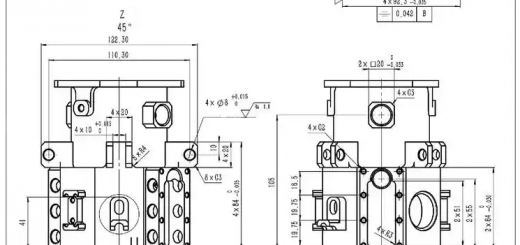

Design CAD modeling: Based on cutting parameters and structural design drawings, use computer-aided design software to establish a three-dimensional digital model.

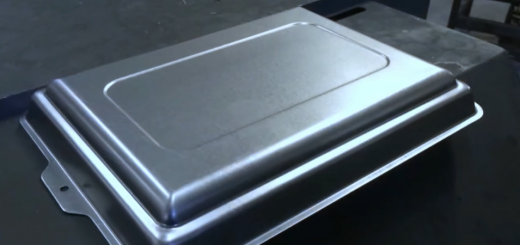

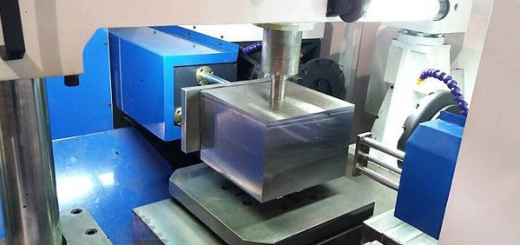

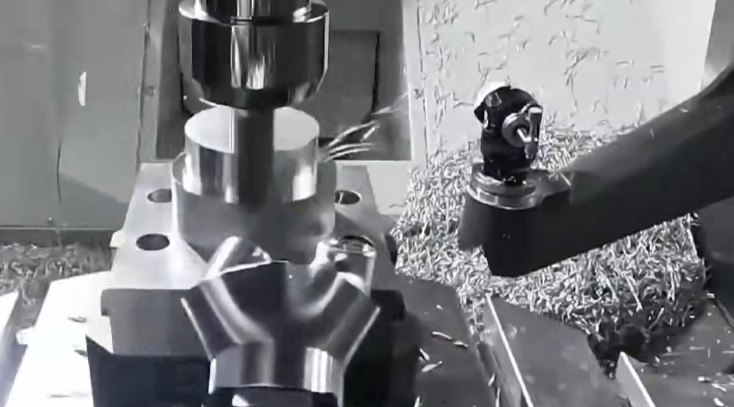

Isometric grinding: Using a CNC equiaxed grinding machine, the tool is controlled based on CAD model data for preliminary shaping, producing rough blanks.

End face grinding: perform end face grinding to achieve the flatness, roughness, and other shape dimensions of the finished end face.

Side grinding: Fine grinding is performed on the side of the blank to obtain a nearly fixed cutting blade shape.

Judging grinding: By observing under a macro mirror, determine whether the grinding quality is qualified.

Grinding the cutting edge: A curved blade type grinding tool is used to grind the cutting edge on the end face.

Blade removal: Use grinding paper to remove the indentation at the exit of the cutting edge.

Coating: A hard alloy or carbide film is deposited on the blade surface by physical vapor deposition method.

Packaging: Paper pressed packaging will be sent to the warehouse and shipped according to customer customization requirements.

Cleaning process of milling cutter

Tool cleaning is an important part of ensuring the quality of cutting workpieces. The traditional manual cleaning method has high labor intensity and inevitably leaves manual operation errors. After long-term testing, R&D personnel have designed a fully automatic fine cleaning system.

The system consists of three cleaning stations, achieving mechanization to replace manual operations. The first station uses ultrasonic heated cleaning solution with high sodium chloride content to generate a large amount of fine foam to remove the dirt on the blade surface.

Subsequently, it enters the spray station and undergoes three washes with high-pressure air and clean water to remove any residue. Finally, there is the step of filtering and drying. After passing through the secondary filter screen, strong air is supplied to blow the surface until there is no water.

The entire production line adopts a curved conveying method to transport the cutting tools forward. Each station is equipped with ultraviolet lamps for sterilization, ensuring a sterile environment. The system can be cleaned in five minutes, and the cleanliness level is significantly better than manual operation. And the automation efficiency is higher.

It solves the problems of traditional manual cleaning, such as difficulty in ensuring operating standards and low efficiency. Ensure the cleanliness and hygiene of tool surfaces, extend their service life, and provide users with higher quality cutting services.

Passivation treatment of milling cutters

Passivation treatment of cutting tools is an effective way to extend their service life. Traditional manual passivation inevitably involves artificial bloating, which is not conducive to fine operation.

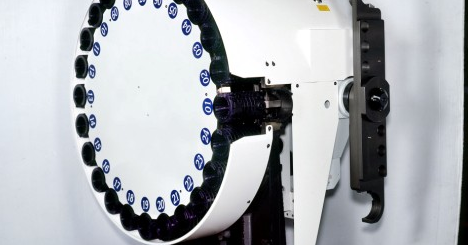

The R&D team spent six months developing a fully automated passivation system. The system consists of a powder spraying device, a turntable, and a computer control cabinet. After cleaning, the cutting tools are placed on the turntable by the handling robot.

The computer automatically adjusts the machining program based on the tool parameters. Driven by efficient compressed air, the powder nozzle accurately sprays the surface passivation tool at different parts of the blade at a high pressure of 500-1000 bar. Due to frequent and detailed pressure changes, it can fully cover every corner area.

At the same time, the turntable will slowly rotate at a speed of 360 ° per second to help evenly distribute the layers. The entire passivation process only takes 10 minutes. Compared to manual labor for 2 hours, there is a significant improvement in efficiency.

Post inspection showed a significant decrease in surface roughness, while the incision was smooth like a mirror. This not only enhances the lifespan of the blade, but also reduces the consumption generated during subsequent cutting. Provide users with longer-term maintenance free services.

Coating technology for milling cutters

The coating treatment of cutting tools is an important part of improving performance. Traditional handmade coatings inevitably suffer from issues of missing layers and unevenness.

The R&D team has developed a fully automatic coating machine using physical vapor deposition technology. The robot transports the processed tools into the turntable, and the rotating system fixes the tools on a rack that can rotate 360 °.

In the vacuum chamber, the plasma generating device evaporates the coating material into a laminar plasma flow. The dedicated control system is responsible for adjusting the braking voltage and substrate temperature to ensure that the plasma uniformly covers the entire surface of the blade.

The full monitoring system checks the coating quality in real-time through sampling analysis. On average, 50 cutting tools can be added to each batch in just 30 minutes, and the coating uniformity is rare in the global industry.

The coated layer can effectively separate the blade from the workpiece, reduce friction and wear during cutting, and greatly improve the tool life and cutting efficiency. Provide users with higher quality services.