Injection Molding Jetting Defect Causes and Solutions

Jetting is one of the common defects that can occur during the injection molding process. Understanding its causes and how to prevent it is important for plastic part manufacturers. This article will discuss what the jetting defect is, as well as the reasons and solutions.

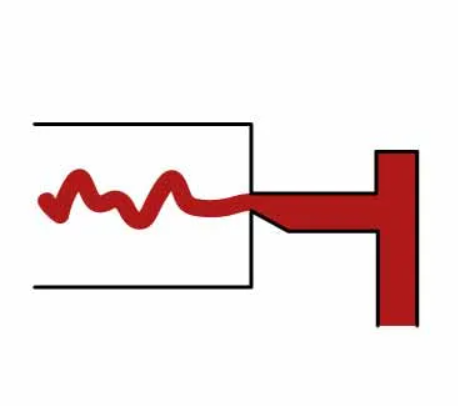

What Is Jetting Defect in Plastic Injection Molding?

Jetting defect is characterized by a snake-like pattern or flow lines on the surface of an injection molded part. When the molten material rapidly flows through the nozzle, the narrow channels or gates, and suddenly enters the open, relatively wide area, the molten body curves like a snake along the direction of flow and quickly cools down after contacting the mold surface. If this portion of the material cannot blend well with the resin that subsequently enters the cavity, it will form jet-flow patterns on the finished product.

When there are significant differences in the cross-sectional areas of the gate and cavity, it often results in jetting defects on the molded part surface. The swirling flow lines caused by jetting negatively impact the aesthetic appearance of parts and can sometimes also weaken mechanical properties if severe enough. Therefore, manufacturers need to analyze the root causes and implement appropriate countermeasures to prevent its occurrence.

How to identify jetting on plastic parts?

To identify jetting in injection molding, carefully examine the surface of the molded parts for obvious flaws, streaks, lines, or distortions, paying particular attention to areas with sharp corners or edges where jetting is most likely to occur. Analyze the surface quality of the molded parts as a whole, looking for uneven texture, roughness, or waviness, and take precise measurements of key dimensions to identify any discrepancies. Evaluate the process parameters, such as injection speed, melt temperature, mold temperature, and cooling time, to determine if any of these factors may be contributing to the jetting. Inspect the mold for potential problems, including poor gate design, inadequate ventilation, and worn-out or damaged surfaces, and analyze the plastic material’s properties, including its melt flow rate, viscosity, and compatibility with the mold surface.

Causes of Injection Molding Jetting Defect

– Narrow or improperly positioned gate: A gate that is too small relative to the cavity size or positioned incorrectly can induce jet-like flow.

– High injection velocity: Excessive melt speed on entering the cavity promotes non-uniform flow distribution.

– Poor melt temperature control: Inconsistent melt temperature leads to fluctuations in viscosity which influence flow behavior.

– Poor plastic material: Materials with a broad molecular weight distribution or insufficient melt strength are prone to jetting.

– Uneven melt distribution: Irregular filling caused by an uneven melt front as it advances into the cavity.

– Cavity design issues: Abrupt changes in flow path cross-section, sharp corners, or thin sections in the design.

– Lower processing temperatures: Insufficient melt/mold temperature decreases melt flowability.

– Higher injection pressures: Excessive pressure promotes jet-like flow into the cavity.

– Entrapped air/moisture in plastic: Compressible contaminants interfere with uniform filling.

Solutions for Injection Molding Jetting Defect

1. Widening the Gate Size

A larger diameter gate reduces flow velocity and helps spread the melt more evenly as it enters the cavity. However, gates shouldn’t be too wide to avoid defects like cold slugs.

2. Optimizing Process Parameters

Fine-tuning screw speed profiles, and pack & hold pressures/times can all influence the filling dynamics to mitigate jetting risks.

3. Properly Raising Temperature

Higher, more consistent melt and mold temperatures increase fluidity for better flow distribution in the cavity. Too high can cause other issues.

4. Modifying Gate Location or Design

Repositioning or altering the gate design can rectify flow irregularities causing jetting in certain areas. Simulation can help evaluate designs. The use of overlapping gates can reduce the flow rate of plastic, thereby reducing the jetting patterns. By using an ear guard or fan-shaped gates, the adhesive can move smoothly from the gate to the mold cavity, reducing the shear stress experienced by the adhesive when passing through the gate. In addition, increasing the size of the sprue and runner, and shortening the sprue length are also considered directions.

5. Refined Cavity Design

Smoothing flow path transitions and removing sharp corners/thin sections via design modifications help uniform filling.

6. Degassed Plastic

Removal of moisture and volatiles in the resin via desiccant drying or vacuum degassing prevents air interference with melt flow.

7. Adjusting injection speed

Adjusting the injection speed can help to reduce jetting. This can include reducing the injection speed or increasing the injection time.

8. Reducing fill pressure

Reduced pressure decreases shear stresses and heat on the melt, minimizing molecular orientation effects. It also lessens velocity-induced jetting during filling. However, pressure shouldn’t be too low to avoid other defects.

9. Use less brittle materials

Brittle materials can exacerbate jetting defects. More ductile and flexible resins with better melt strength will resist jetting caused by abrupt changes in flow behavior better than brittle plastics.

10. Narrow the molecular weight distribution

Materials with a narrow MW distribution have more uniform molecular sizes that flow in a more homogeneous and predictable manner. This makes them less prone to jetting issues.

11. Lower viscosity grade of the same material

For parts with considerable wall thickness variations, using a lower viscosity grade of the same material family can improve flowability into thin sections and reduce instability-induced jetting.

12. Add flow aids or processing aids

Minimally loaded additives like process aids can enhance melt strength and stability during filling, preventing jetting caused by non-uniform flow front advancement.

While optimizing individual factors is helpful, a holistic approach examining all influencing elements is often needed to fully resolve stubborn jetting issues. Manufacturers also leverage Moldflow simulations to study melt flow patterns and identify design/process modifications for continuous improvement. With diligent analysis and preventive measures, jetting defects can effectively be prevented during production. Of the various solutions available, optimizing key process parameters such as injection pressure, and melt/mold temperatures through systematic experimentation typically yields the best results.