Precision of Thread Whirling: How Burr-Free Bone Screws Are Manufactured

Bone screws play a critical role in modern medicine, holding fractured bones together and aiding in the healing process. These screws must be manufactured with exceptional precision to ensure safety and functionality. One of the most advanced techniques for creating the intricate threads on these screws is thread whirling. Here we break down the step-by-step manufacturing process, the tools and machines involved, and why thread whirling is the best method for producing burr-free bone screws.

What Is Thread Whirling?

Thread whirling is a high-precision machining process used to create threads on cylindrical components, such as bone screws. Unlike traditional thread-cutting methods, thread whirling employs a high-speed rotating tool that produces threads with exceptional precision, smoothness, and consistency. This method is particularly critical for bone screws, which require complex geometries and burr-free surfaces to ensure they function safely in medical applications.

How To Make Bone Screws with Thread Whirling?

The production of bone screws involves several meticulous steps, each designed to ensure the highest levels of precision and quality.

1. Material Selection

Bone screws are typically manufactured from biocompatible materials such as surgical stainless steel or titanium. These materials are strong, durable, and safe for use in the human body. For demonstration purposes, brass is occasionally used during testing to provide better visibility of the machining process.

2. Pre-Turning the Part

The manufacturing process begins with pre-turning the part to prepare it for threading. While thread whirling tools are capable of forming threads without pre-turning, this step is sometimes necessary to accommodate specific insert sizes or part dimensions.

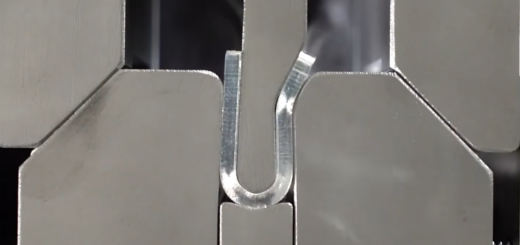

3. Cutting the Starting Notches

A milling tool, such as a Harvey end mill, is used to create the starting notches on the screw. This ensures the thread whirling process starts cleanly and accurately.

4. Thread Whirling

Thread whirling is the heart of the process. Custom thread whirling rings and inserts—like those from PH Horn—are used to form the screw threads. These tools are designed with specific angles and geometries to match the unique requirements of each bone screw.

5. Ensuring a Burr-Free Finish

After the threads are formed, a milling tool is used to remove any residual burrs. This step is critical because burrs can break off and enter the bloodstream, leading to severe medical complications. A burr-free surface ensures the screw is safe and functional.

The Importance of Chip Flushing in Thread Whirling

One of the challenges in thread whirling is managing the chips generated during the machining process. The centrifugal force of the whirling tool holder can trap chips inside, reducing tool life and potentially damaging the threads. To prevent this, a coolant line is used to flush the chips out, ensuring a clean and efficient process.

Tools and Machines for Bone Screw Manufacturing

The manufacturing of bone screws requires advanced tools and machines to achieve the necessary precision.

The Torno CT26

The Torno CT26 is a versatile machine that combines thread whirling and B-axis capabilities. This integration allows manufacturers to perform multiple operations in a single setup, saving time and increasing accuracy. Few other machine tool builders offer this level of functionality in one system.

High-Frequency Air Spindle

For creating the small hex features on the screw head, a 1mm end mill paired with a high-frequency air spindle is used. Operating at 80,000 RPM, this setup minimizes tool pressure and allows for fast, precise milling.

Custom Inserts: The Key to Precision

Thread whirling relies on custom inserts designed specifically for the thread profile being manufactured. Each insert is tailored to the geometry of the screw, ensuring consistent and accurate thread formation. These inserts are mounted in a thread whirling ring and aligned at an angle to match the thread pitch.

Using a shadow graph, manufacturers can inspect the thread profile and verify that it matches the screw’s design specifications. This attention to detail ensures that the final product meets the stringent requirements of medical applications.

Why Thread Whirling Is the Best Choice?

Thread whirling offers several advantages over traditional thread-cutting methods:

- Precision: The process ensures perfectly aligned and consistent threads.

- Burr-Free Finish: The high-speed cutting and post-processing steps eliminate burrs, making the screws safer for medical use.

- Efficiency: Thread whirling is faster and more reliable than conventional methods, especially for complex geometries.

When it comes to manufacturing bone screws, thread whirling is the gold standard for achieving precision, safety, and quality.

Bone Screw Applications

The threads on bone screws vary depending on their intended application. Some screws are designed to pass through dense bone, while others are meant for softer, spongy bone. Still, others are used to secure medical devices in place. This diversity means that bone screws come in a wide range of thread profiles and sizes, all of which can be produced using thread whirling.