Top 5 Best Desktop 5-Axis CNC Machines & How To Setup (2024)

5-axis CNC machines are revolutionizing the manufacturing industry by enabling the production of complex surfaces with higher accuracy, better surface finish, and faster build times. In this guide, we’ll explore the world of desktop 5-axis CNC machines and provide insights on how to set one up.

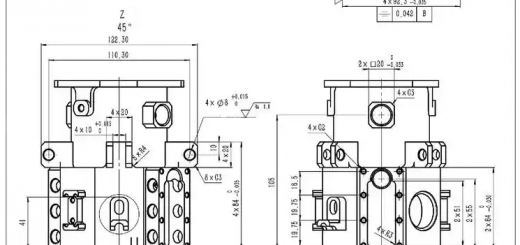

Introduction to 5-Axis CNC Machines

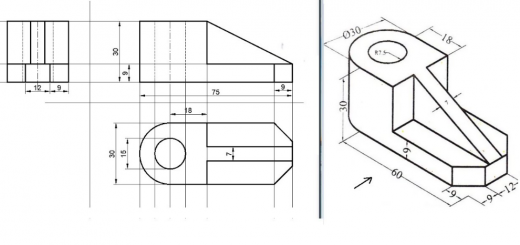

5-axis CNC machines are a leap forward in manufacturing technology, allowing for precision machining from virtually any angle. This capability results in higher accuracy, superior surface finishes, and quicker production times. Unlike traditional 3-axis systems, 5-axis machines move across five different axes simultaneously, which can drastically reduce the machining time and increase efficiency.

Choosing the Right 5-Axis CNC Machine

When selecting a 5-axis CNC machine, consider the following models based on your needs and budget:

1. Chinese 5-Axis CNC Machine

- Price: Approximately $3,600

- Build Volume:110 x 125 x 125 mm

- This model may be the most budget-friendly option available, making it a great entry point for those new to 5-axis CNC machining.

2. Pocket NC

- Price: Starts at $6,000

- Build Volume:116 x 127 x 90 mm

- Known for its simplicity and ease of use, the Pocket NC is ideal for desktop operations in spaces like offices or classrooms.

3. Diabase H-Series

- Price: Starting at $10,000

- Build Volume: 150 x 275 x 275 mm in 5-axis mode

- This hybrid machine not only supports CNC machining but also 3D printing, offering a versatile solution for complex fabrication needs.

4. Ethereal Halo

- Price: $25,000

- Build Volume: Cylindrical 150 x 150 x 150 mm

- Manufactured in India, this machine combines CNC milling and 3D printing capabilities in a single unit.

5. 5-Axis Maker

- Price: Starts at $6,500

- This British-made machine was first launched on Kickstarter and has undergone several improvements. It’s notable for its large build volume and affordability, making it a top choice for desktop fabrication.

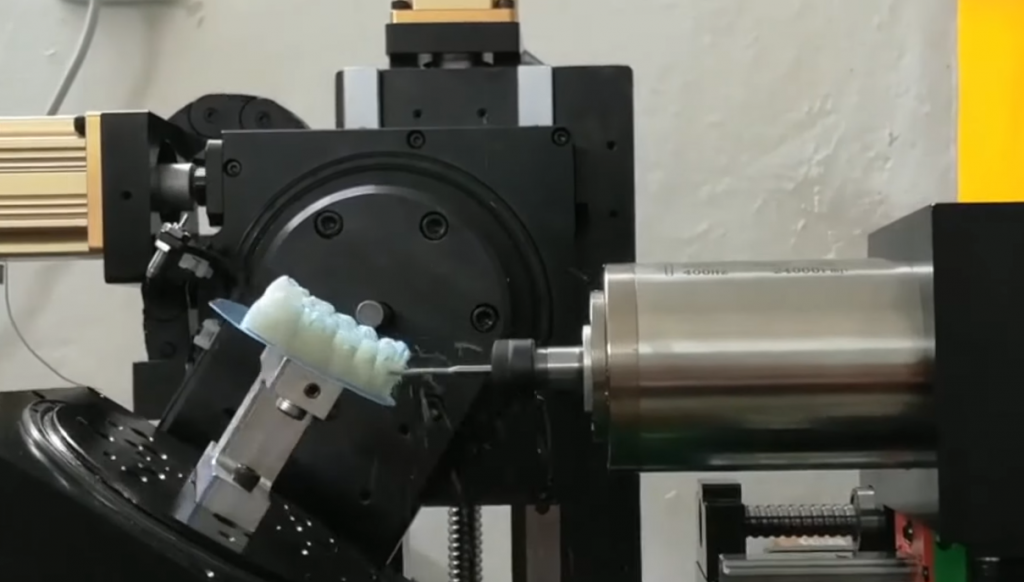

Setting Up Your 5-Axis CNC Machine

Once you’ve selected your 5-axis CNC machine, setting it up involves several key steps:

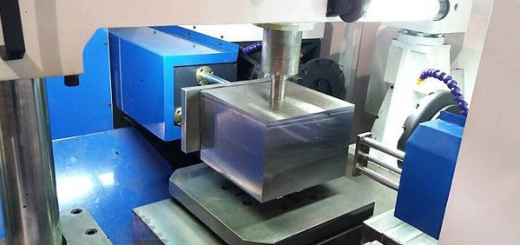

- Assembly: Follow the manufacturer’s instructions carefully to assemble your machine. This may involve setting up the frame, attaching the spindle, and ensuring all moving parts are correctly aligned and lubricated.

- Installation of Software: Install any necessary software that comes with your machine. This might include CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software specifically designed for 5-axis machining.

- Calibration: Proper calibration is crucial for achieving precise results. Calibrate the machine according to the manufacturer’s guidelines to ensure all axes are moving correctly and that the tool paths are accurate.

- Tool Setup: Install the cutting tools or heads required for your specific project. This could range from standard drill bits to more specialized milling tools.

- Material Setup: Secure your material onto the machine’s bed. Make sure it is firmly fixed to avoid any movement during the machining process.

- Test Runs: Before committing to your final project, perform test runs to check the accuracy of the machine’s movements and the quality of the cut. Adjust settings as needed.

Setting up a 5-axis CNC machine is a substantial investment in both time and money, but the payoff in terms of manufacturing capabilities is unparalleled. Whether you’re a hobbyist looking to expand your crafting limits or a small business aiming to produce complex parts, a 5-axis CNC machine can significantly enhance your production capabilities.

Remember, the key to successful machining lies in careful setup, thorough testing, and ongoing adjustments. With the right preparation and understanding, your 5-axis CNC machine will become an invaluable part of your fabrication arsenal.